Pipes

- Home

- Product Range

- Pipes

Pipes

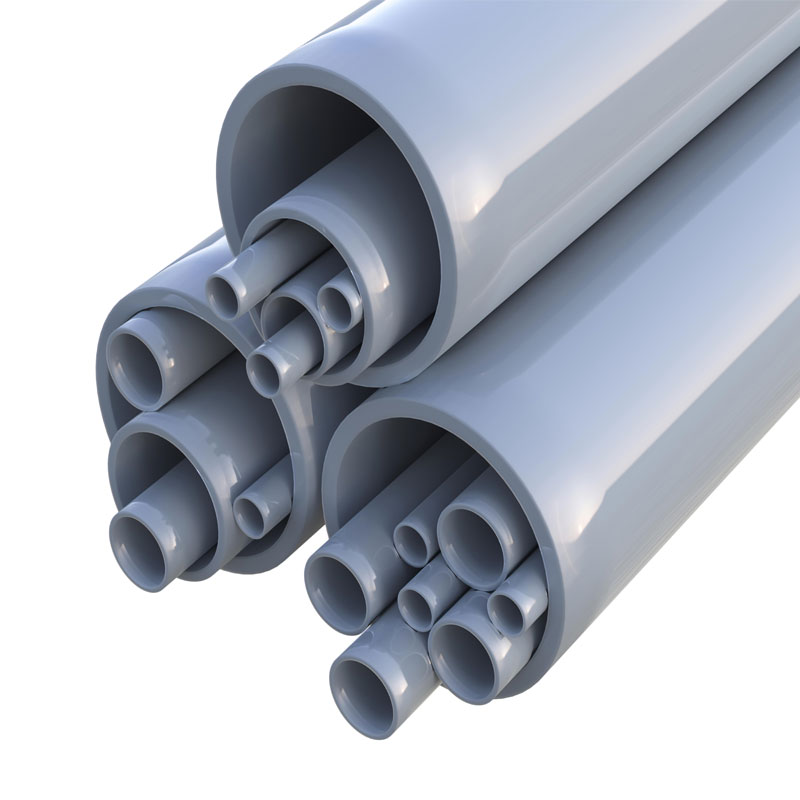

Pipes are cylindrical conduits used for the transportation of fluids (liquids and gases) or for structural applications. They come in various materials, sizes, and shapes, and they play a fundamental role in a wide range of industries, including plumbing, construction, manufacturing, and energy. The selection of the right type of pipe depends on the specific requirements of the application, including the type of fluid being transported, pressure conditions, temperature, and environmental factors.

Types of Pipes:

Steel Pipes: Steel pipes are robust and durable, making them suitable for a wide range of applications, including water and gas distribution, structural support, and in industries such as oil and gas.

Copper Pipes / Copper Tubes: Copper pipes are known for their corrosion resistance and excellent thermal conductivity. They are commonly used in plumbing systems for water supply, heating, and cooling.

PVC Pipes: PVC (polyvinyl chloride) pipes are lightweight, cost-effective, and resistant to corrosion. They are widely used in plumbing for water distribution, drainage systems, and irrigation.

HDPE Pipes: High-density polyethylene (HDPE) pipes are lightweight, flexible, and resistant to corrosion. They are commonly used for water supply, irrigation, and in industries such as mining.

PEX Pipes: PEX (cross-linked polyethylene) pipes are flexible and resistant to scale and chlorine. They are commonly used in plumbing for water supply and radiant heating systems.

Cast Iron Pipes: Cast iron pipes are durable and resistant to fire, making them suitable for drainage and sewer systems. They are known for their long lifespan and ability to withstand heavy loads.

Aluminum Pipes: Aluminum pipes are lightweight and corrosion-resistant. They find applications in industries such as aerospace, automotive, and construction.

Stainless Steel Pipes: Stainless steel pipes are known for their corrosion resistance and strength. They are used in various applications, including water supply, food processing, and chemical industries.

Considerations in Choosing Pipes:

Material Compatibility: Select a pipe material that is compatible with the type of fluid being transported to prevent corrosion or contamination.

Pressure Rating: Consider the pressure requirements of the application and choose pipes with the appropriate pressure rating.

Temperature Resistance: Ensure that the chosen pipe material can withstand the temperature conditions of the application, especially in systems involving hot or cold fluids.

Cost: Consider the cost-effectiveness of the pipe material, taking into account factors such as installation, maintenance, and longevity.

Environmental Impact: Evaluate the environmental impact of the chosen pipe material, especially in applications where sustainability and environmental considerations are important.

Installation and Maintenance: Consider the ease of installation and maintenance, as well as any specific requirements for joining methods and fittings.

In conclusion, pipes are foundational components in various industries and applications, serving critical functions in fluid transportation, structural support, and infrastructure development. The proper selection and installation of pipes are essential for ensuring the reliability, safety, and efficiency of systems across different sectors.